Zero Liquid Discharge

Most industrial processes rely on fresh water, which often results in a wastewater stream. This polluted and contaminated water represents a cost for treatment, discharge or offsite disposal, and environmental concerns. Zero Liquid Discharge (ZLD) systems are designed to treat this wastewater, letting you recover and reuse both water and/or valuable chemicals directly at the production site. This is crucial for achieving profitable and circular solutions.

Reuse water, recover value

- Increase the efficiency of water usage by minimizing liquid waste and treating water for reuse

- Some processes may recover valuable resources such as metals minerals or chemicals

- Easily adjustable systems are future-proof to your growing needs and changing regulations

- Less waste means lower disposal costs and reduced need for new resources (chemicals for instance)

Every industrial effluent stream is different and each has its own challenges. That’s why Alfa Laval’s Zero Liquid Discharge (ZLD) solutions are engineered with precision, combining advanced technology and deep process expertise to minimize waste and, when needed, eliminate wastewater discharge. From modular, pre‑assembled systems for fast integration to fully customized designs for unique processes, we work closely with you to ensure optimal performance, regulatory compliance, and a positive impact on both your business and the planet.

Want to learn more?

With a Zero Liquid Discharge system in your process, you can achieve:

Water recovery

With an ZLD system in your process you can recover the solvent (water) for reuse in the process, up to 98%. By cleaning and reusing water, you can limit the amount of fresh water that enters your plant and reduce or even eliminate wastewater.

Resource recovery

The solids produced vary and include salts or chemicals that can be resold or reused in the initial process. This turns what was previously waste into a product, improving the profitability of your business

Waste minimization

Reduce or remove liquid effluent due to constraints in downstream water treatment. This reduces the need for waste storage disposal and reduces transportation costs.

What is Zero Liquid Discharge (ZLD) and why is it important?

ZLD technology addresses the growing water challenges that industries are facing, including waste and pollution minimization, water scarcity, compliance with legislation and circularity. The market is significant and expanding, driven by those trends. Most industrial processes rely on fresh water, which often results in a wastewater stream. This polluted and contaminated water represents a cost for treatment, discharge or offsite disposal, and environmental concerns. ZLD systems are designed to treat this wastewater, letting you recover and reuse both water and valuable chemicals directly at the production site. This is crucial for achieving profitable circular solutions. By reusing water and recovering value with ZLD technology, industries make their operations more sustainable and efficient. A system from Alfa Laval enhances resiliency, aligns profit and sustainability goals, leading to a more robust business, less vulnerable to external changes.

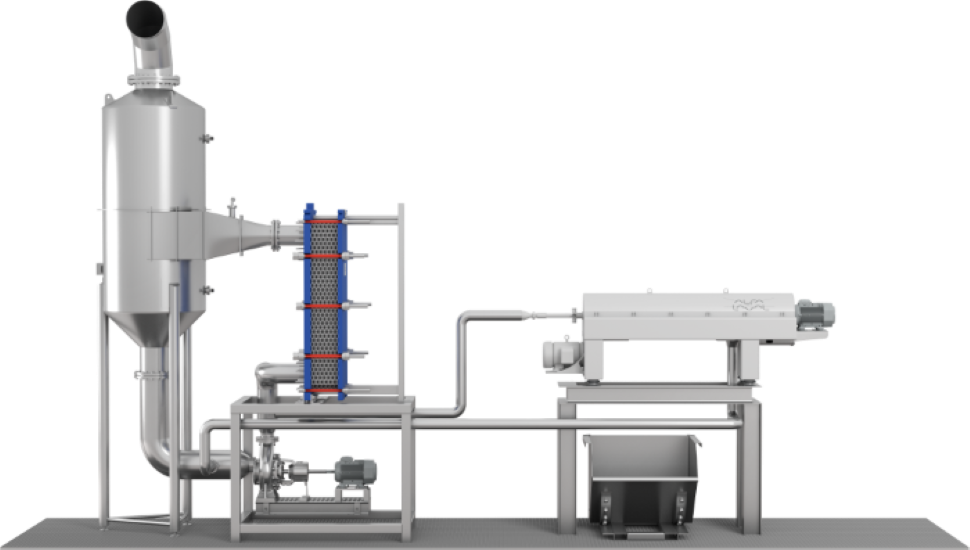

ZLD is a combination of technologies

The most common process steps follow this sequence:

- Chemical and/or physical pre-treatment of the raw wastewater. The aim is to prepare the stream for the requirements of the downstream steps. Typical examples of pre-treatment can be chemical reaction, precipitation, flotation or filtration.

- Membrane treatment and pre-concentration. Reverse osmosis is a common option to decrease the wastewater volume as much as possible at minimal cost.

- Thermal evaporation of the brine (reject) from the membrane step. Thermal evaporation further reduces the brine volume.

- Crystallization of the concentrated brine. It is during this step that the solids (crystals) are produced for disposal or reuse, achieving Zero Liquid Discharge.

Explore the features of the Zero Liquid Discharge system

Modular systems in standard configuration or customized to your needs

We provide modular or custom evaporation systems, including energy-efficient Mechanical vapor recompression (MVR) units powered by electricity and Multiple Effect Systems using steam, hot water, or waste heat. Both types are available as pre-assembled modules, stand-alone units, or in ZLD configurations with decanter centrifuges for dry solids output.

Industries and applications

Highly adaptable, our Alfa Laval AlfaFlash ZLD systems can be used across a range of demanding duties. We bring proven experience across a wide range of processes and industries, among others:

Mining and metals

HVO

Battery production and recycling

Alfa Laval opens state-of-the-art service centre that recycles almost 100 percent of its water

Alfa Laval's new service centre in Frechen, Germany, will be one of the largest for plate heat exchangers in the world. In addition, it is also a technically advanced and sustainable facility, capable of recycling almost 100 percent of its water using Alfa Laval Zero Liquid Discharge technology.