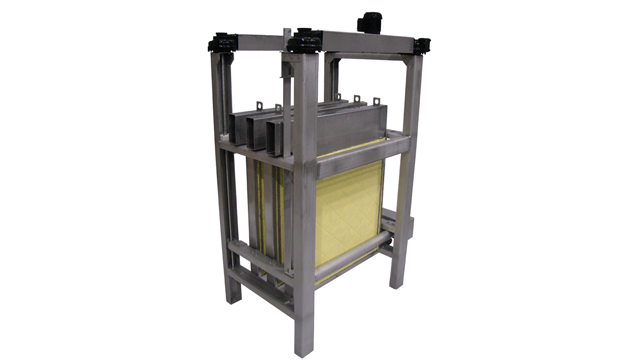

ASH Iso-Disc®

The high-performance cloth media filter captures solids to produce reuse-quality filtrate in a continuous operating process. This advanced wastewater filtration system is designed for tertiary filtration and final polishing in municipal and industrial wastewater treatment.

Experience the benefits of a simple, efficient, and flexible wastewater filtration system

- High-quality tertiary filtration with California Title 22 Water Reuse Certification

- Easy to operate with fully automatic cloth media filtration and uninterrupted operation during the backwashing cycle

- Effortless maintenance with real-time individual filter element monitoring and streamlined upkeep

- Robust cloth media filter design

- Small footprint-to-flow ratio

Following its acquisition of Ashbrook Simon-Hartley, Alfa Laval also offers a tertiary filtration system. Utilizing innovative cloth media filtration technology, the Alfa Laval ASH Iso-Disc® wastewater filter ensures efficient and reliable performance for superior water quality. The wastewater filtration system flexibly fits your specific needs and can be easily expanded. Both square and rectangular cassettes fit within the path of the incoming water and are available to cater to different installation configurations. It also allows for individual visual assessment of the effluent flow rate and quality.

ASH Iso-Disc®: Advanced Cloth Media Filtration for Tertiary Wastewater Treatment

ASH Iso-Disc® is a compact, cost-effective tertiary filtration technology. Utilizing innovative cloth media filtration, the polishing filter is designed to remove solids of less than 10 microns. This outside-in depth filtration enhances solids capture and improves operation during high solids loadings and load variations.

A single cloth media filter unit can treat from 100 up to 20,000 m³ of wastewater per day. Unlike other wastewater filtration systems, it uses 100% of the available filtration surface at all times, maximizing unit effectiveness and providing a very small footprint-to-flow ratio.

Operational Flexibility and Easy Maintenance

The unique ASH Iso-Disc® cloth media filter design allows easy monitoring of individual filter elements through visual inspection or sample analysis (e.g., NTU). One filter element can be isolated, removed, cleaned, and replaced while others remain operational. This flexibility mitigates site upsets and enhances single-duty plant availability.

The simple nature of the wastewater filtration system, with very few moving parts, ensures that operation and maintenance requirements are kept to a minimum. There is no need for specialist maintenance tasks or upskilling of local operating teams, making cloth media filtration solutions ideally suited to remote or unmanned site locations.

How does the cloth media filter work

The gravity-driven continuous Alfa Laval ASH Iso-Disc® cloth media filter removes residual solids from wastewater, achieving a high final effluent quality suitable for reuse. It is a compact, high-capacity, and cost-effective alternative to traditional sand filters.

The use of the fixed-filter media design reduces overall horsepower and permits the removal of each individual filter plate of the wastewater filtration system while the filter remains in operation. During backwash, the filter plates remain fixed while the dynamic, bi-directional, linear backwash manifold serves as a header for the removal of solids from the pile cloth media.

At the beginning of the backwash cycle, which is initiated by headloss across the filter, electrically actuated valves segregate the backwash header and clean the filter plates on that portion of the header. This ensures complete cleaning of the cloth media filter while minimizing the rate at which backwash water is returned to the treatment facility.

Automated cleaning process of ASH Iso-Disc® cloth media filtration elements

Cleaning the cloth media filtration elements is a straightforward, automated procedure. Initiated by a rising water level, a horizontal suction manifold travels up and down each element while a centrifugal pump gently removes the solids, resulting in an even clean over the entire surface of the filter media. The pile cloth media allows for complete cleaning during backwash, utilizing filtered water from inside the filter plate. If required, the cloth media can be replaced and the filter plate re-installed in a matter of minutes, all while the filter continues to function without interruption. Typical backwash frequency is less than 1–2 times per hour during design peak (FFT), with much lower backwash throughout the day. During normal operation, the average backwash water is less than 2% of the total feed flow.

The ASH Iso-Disc® tertiary filtration technology can be installed into a concrete structure (supplied by others), pre-fabricated carbon steel with epoxy coating, or stainless steel tanks. The cloth media filter can be used in wastewater treatment plants, to polish industrial wastewater and remove accumulated inorganic solids in the food and beverage industry. It can also treat surface water for use in cooling towers or other process water requirements.

Enhancing filtration efficiency with cloth media filters

The performance of the ASH Iso-Disc® is second to none, as the cloth media filter is capable of capturing solids down to less than 10 microns. Its innovative design eliminates rotating underwater seals, ensuring superior filtrate quality and preventing any cross-connection between influent and filtrate. This not only guarantees exceptional performance but also requires significantly less maintenance.

Many wastewater treatment plants are now adopting cloth media filters as a pre-treatment step for downstream microfiltration or ultrafiltration membranes. By polishing the secondary effluent, these filters enhance both the filtration efficiency and the economic viability of the membranes, making them an indispensable component in modern wastewater treatment processes.

Advanced tertiary filtration

The gravity-driven, continuously operating polishing filter uses completely submerged filter media, ensuring 100% active filtration area at all times. The outside-to-inside flow through the pile cloth media provides superior depth filtration compared to screens. All internal or submerged components are made of corrosion-resistant stainless steel or non-metallic materials. For retrofits, the square or rectangular filter plates easily fit into existing basins and require only a low driving force of a 30 cm water column.

Produce high-purity filtrate from applications such as tertiary filtration, process streams, surface water treatment, and other water reuse, while handling solids and hydraulic loading with a small footprint-to-flow ratio.