How a disc stack centrifuge works

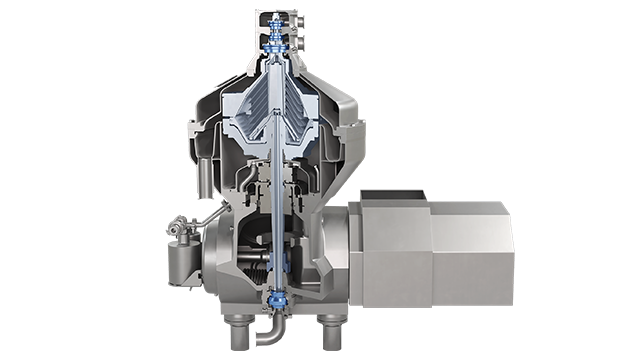

A disc stack centrifuge, also referred to as a disc stack separator, is a separation technology used to isolate solids and liquids based on their density differences. If you are wondering how does the centrifuge work, the process is straightforward: centrifugation applies mechanical force to achieve separation.

Similar to a settling tank, disc stack separators use the force of gravity to separate liquid with a specific density from other liquids and solids. Unlike a settling tank which uses retention time as the main parameter for liquids of different densities to divide into layers and solids to precipitate to the tank, centrifugal separators use mechanical force to separate liquids and solids with different densities from each other.

Using the force of gravity

A disc stack centrifuge works like a settling tank wrapped around the center line of a rotating bowl. When the bowl spins rapidly, the effect of gravity is replaced by a controllable centrifugal force, known as G-force, that can be up to 10,000 times stronger than natural gravity.

G-force allows a disc stack centrifuge to separate liquids from other liquids and solids with high accuracy, speed, and easy control. The disc stack inside the bowl increases the effective separation area, improving efficiency. As a result, the disc stack centrifuge working principle delivers faster separation, higher quality, and greater yield compared to gravity-based methods.

Solids that concentrate at the outer edge of the bowl are removed continuously, intermittently, or manually, depending on the solids volume in each application.

To boost efficiency, conical plates are stacked inside the bowl to create a larger separation surface area. These bowl disc stacks accelerate the precipitation of solids from liquids.

Disc stack centrifuge designs for solids handling

How does a disc stack centrifuge work? It separates solids and one or two liquid phases using very high centrifugal forces. As the bowl rotates, solids are pushed to the periphery, while the lighter liquid phases form concentric inner layers. Separation can be discontinuous or continuous, depending on the amount of solids.

Types of separator design

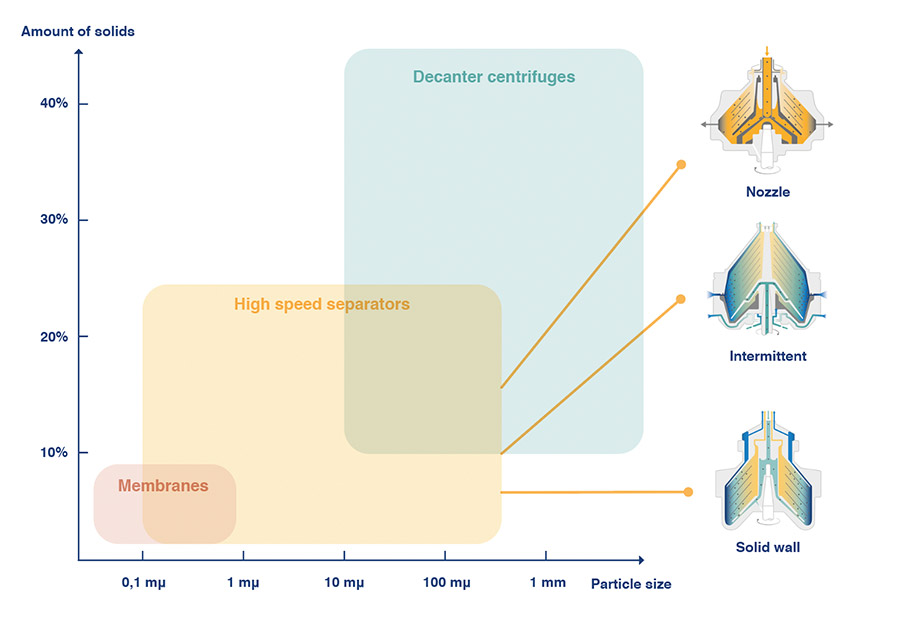

Disc stack centrifuges use different mechanisms for solids handling, based on the duty required:

- Solid-wall separator: Operation stops to open the bowl and remove solids manually.

- Intermittent solids discharge separator: Ports at the bowl periphery open at controlled intervals to remove the collected solids.

- Continuous solids discharge separator: Nozzles at the periphery continuously discharge solids and liquids during operation.

Disc stack centrifuge designs for different separation duties

Disc stack centrifuges are generally used for commercial and industrial separation duties that involve liquid-liquid separation and liquid-solid separation.

- Liquid-liquid separation involves: Two immiscible liquids of different densities.

- Solid-liquid separation involves:

- Removing solids from a liquid to recover valuable by-products and discharging the liquid for treatment as effluent,

- Recovering a valuable liquid from solids and discharging solids for treatment as waste,

- Recover both solids and liquids as valuable products, or

- Removing solids from a liquid before cleaning the liquid prior to discharge to prevent contamination to the environment. - Liquid-liquid-solid separation involves: The separation of three distinct phases, which is the most challenging separation duty. Here no other technology can compete with disc stack separation technology.

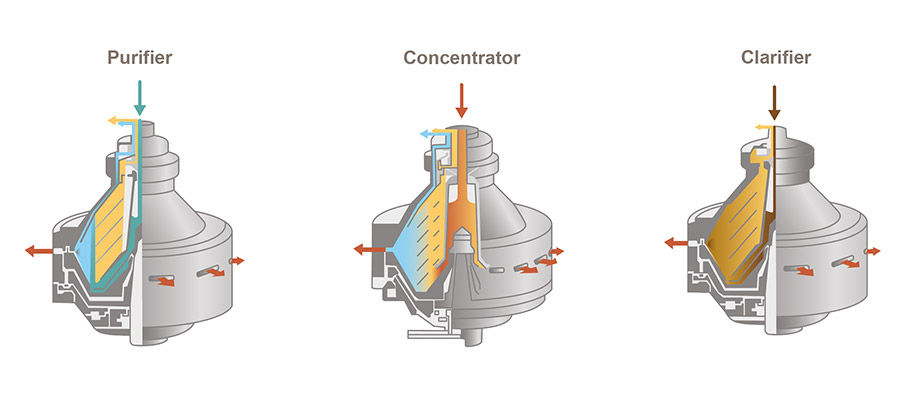

Generally speaking, there are three types of separators depending on the type of separation duty: clarifiers, purifiers, concentrators.

Clara 450 is an example of a separation system with a clarifier - used in the food, beverage and pharma industry.

Clarifier

A clarifier is a centrifugal separator for solid – liquid separation, that removes solids such as particles, sediments, oil, natural organic matter and colour from process liquids. In doing so, the process liquid becomes clear.

Applications

Alfa Laval clarifiers are engineered for use in various applications within food and beverage, marine and industrial fermentation industries. For instance, in beverage applications clarifiers are used in processing of fruit juices, wine, tea and coffee. In industrial fermentation clarifiers are a key component in microalgae, bacteria and yeast fermentation processes. In Marine industry clarifiers are applied for cleaning of scrubber water in system for the cleaning of exhaust gasses.

Concentrator

The Alfa Laval concentrator is a centrifugal separator designed to separate three different phases, one solid phase and two liquid phases of different densities, and clean the densest/heaviest liquid phase.

Applications

Alfa Laval concentrators are widely used in various industries, such as food, beverage processing and marine applications. In vegetable oil and animal fat refining industries concentrators are used for processes continuous degumming, neutralization, dewaxing, and washing. In beverage processing they are used in deoiling and oil recovery applications, such as citrus juice de-oiling and cold pressed peel oil concentration and polishing. In Marine industry Alfa Laval concentrators are used in the cleaning of bilge water.

An AFPX system can be configured as a concentrator and used for fish and meat extraction processes.

A Flex module typically includes a purifier for removing water from diesel oil or

lube oils.

Purifier

A purifier is a centrifugal separator for liquid – liquid – solid separation, that separates two liquids of different densities, and a solids, such as water, oil, and fines, from each other. Using a purifier the light liquid phase is typically the large fraction which is meant to cleaned.

Applications

Alfa Laval purifiers are engineered for multiple applications across industries, such as food and beverage, marine and energy. These premium quality centrifugal separators are suitable for processing plants of any size. In food industry they are typically used in fats and edible oil processing, such as vegetable oils, lard, tallow and fish oil. In Marine purifiers are mainly used for the cleaning of engine lube oils.

Separatorul inovator

Doriți să aflați mai multe despre inovațiile noastre în tehnologia de separare? Faceți clic pe link-ul de mai jos. Alfa Laval a inventat primul separator cu stivă de discuri și a fost lider în dezvoltarea tehnologiei centrifuge timp de peste un secol. Suntem bucuroși să împărtășim cu dumneavoastră expertiza pe care am dobândit-o de-a lungul timpului. Vizitați baza noastră de cunoștințe Separator Innovator pentru a afla mai multe despre progresele în separare și pașii pe care Alfa Laval îi face pentru a continua revoluționarea tehnologiei.