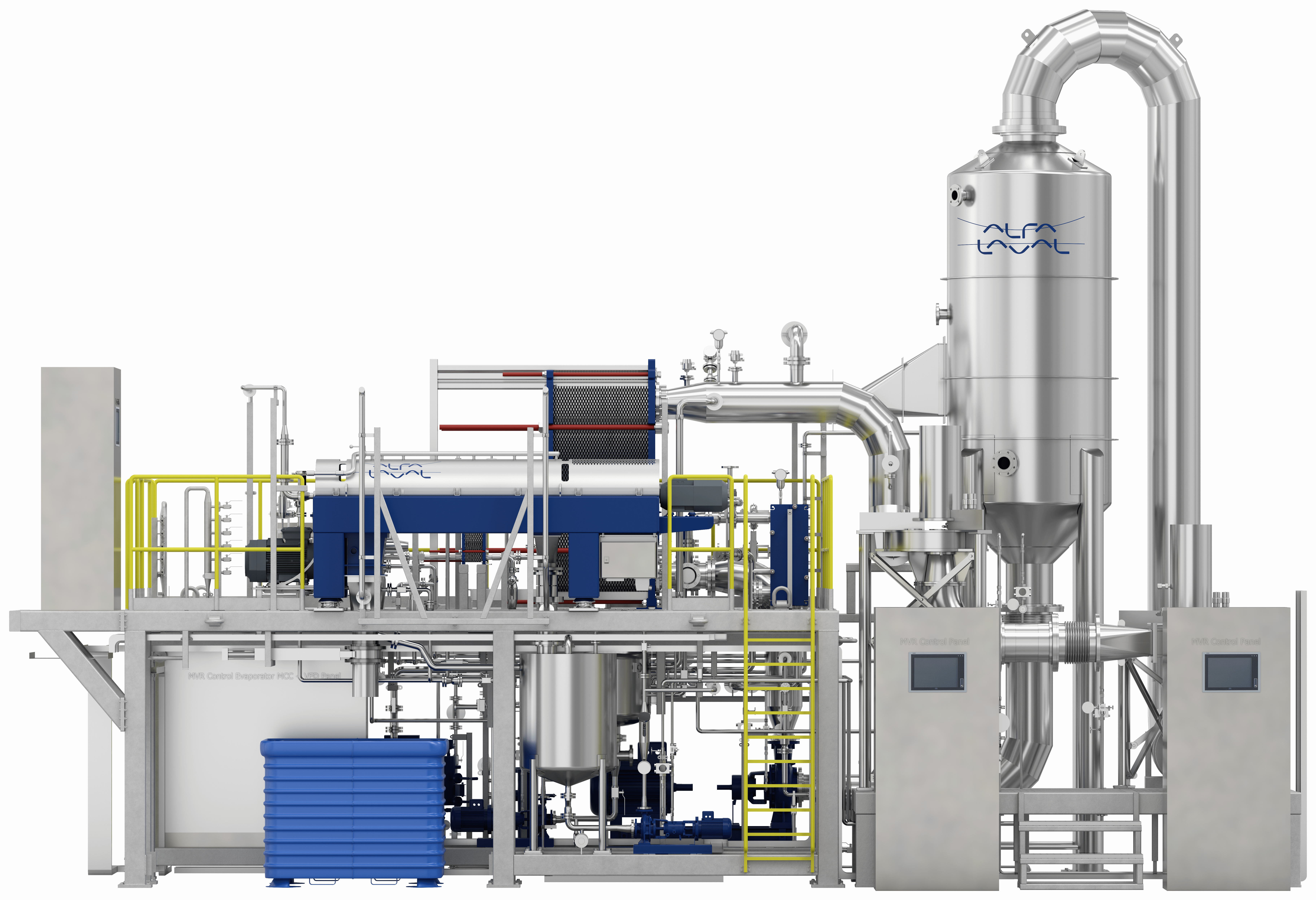

AlfaFlash ZLD

Reuse water and recover value from your waste with an AlfaFlash ZLD system. Featuring the AlfaFlash evaporator and an optional decanter centrifuge, ZLD systems efficiently remove solids from wastewater and other liquids. You can recover valuable dissolved and suspended materials in your process to re-use or sell. And if you have an industrial process that uses significant amounts of water, then you can recycle and reuse water that has been previously discharged, reducing disposal costs.

Modular or customized system for ZLD and process crystallization

- Wastewater elimination

- High purity distillate water that can be re-used, recovering up to 98% of water used in process

- Solids minimized, for re-purpose or minimal disposal costs

- High energy efficiency

- Compact yet robust installation, ideal for a wide range of applications

AlfaFlash ZLD systems eliminate liquid wastewater discharge, generate solids for disposal or reuse, and recycle high-purity distillate water that can be beneficially reused. AlfaFlash ZLD system help both the environment and your bottom-line and are easily adjusted to meet every-changing regulations. Alfa Laval’s proven track record and extensive experience in both thermal solutions and separation technology ensure a cost-efficient solution that incorporates maximum water reuse and high energy efficiency in industrial and food applications.

What is Zero Liquid Discharge (ZLD) and why is it important?

ZLD technology addresses the growing water challenges that industries are facing, including waste and pollution minimization, water scarcity, compliance with legislation and circularity. The ZLD market is significant and expanding, driven by those megatrends. Most industrial processes rely on fresh water, which often results in a wastewater stream. This polluted and contaminated water represents a cost for treatment, discharge or offsite disposal, and environmental concerns. ZLD systems are designed to treat this wastewater, letting you recover and reuse both water and valuable chemicals directly at the production site. This is crucial for achieving profitable circular solutions. By reusing water and recovering value with ZLD technology, industries make their operations more sustainable and efficient. A ZLD system enhances resiliency, aligns profit and sustainability goals, leading to a more robust business, less vulnerable to external changes.

ZLD is a combination of technologies

The goal of a ZLD system is to minimize liquid waste and convert it into reusable clean water and solids that can be used, sold, or safely disposed of. A ZLD system combines technologies to reduce wastewater as much as possible, while producing concentrated solids and high-quality water at the end. The most common process steps follow this sequence:

- Chemical and/or physical pre-treatment of the raw wastewater. The aim is to prepare the stream for the requirements of the downstream steps. Typical examples of pre-treatment can be chemical reaction, precipitation, flotation or filtration.

- Membrane treatment and pre-concentration. Reverse osmosis is a common option to decrease the wastewater volume as much as possible at minimal cost.

- Thermal evaporation of the brine (reject) from the membrane step. Thermal evaporation further reduces the brine volume.

- Crystallization of the concentrated brine. It is during this step that the solids (crystals) are produced for disposal or reuse, achieving Zero Liquid Discharge.

Learn more about our ZLD systems!

Alfa Laval ZLD systems are robust compact solutions for absolute minimization of liquid discharge in. Highly adaptable, they can be used across a range of demanding duties in various industries for wastewater reduction as well as recovery of product, and of water suitable for reuse. Our proven track record and extensive experience in both thermal solutions and separation technology ensure a cost-efficient solution.

Whitepaper: How to save and reuse water with Zero Liquid Discharge

Learn how ZLD technology addresses the growing water challenges that industries are facing, including waste and pollution minimization, water scarcity, compliance with legislation and circularity.

Modular systems in standard configuration or customized to your needs

Mechanical vapor recompression (MVR)

- Requiring electricity as utility

- Significantly less energy consumption compared with steam driven systems

- Available in 1,5-6 ton/hour evaporative capacity or to your specific capacity needs in a customized configuration

- Available as pre-assembled module

- Available in ZLD configuration equipped with crystal dewatering decanter centrifuge to produce a dry solids phase, and as stand-alone evaporator.

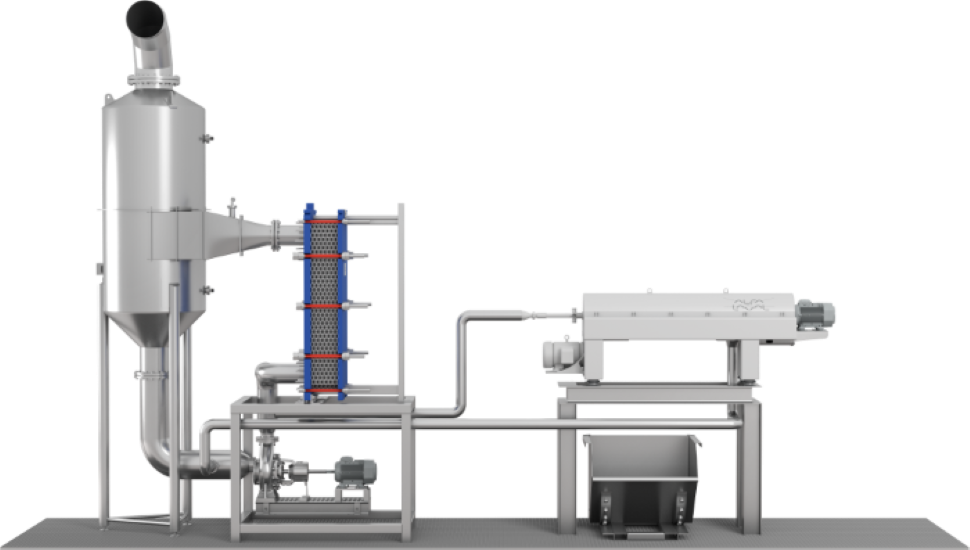

Multiple effect systems

- Available Multi-effect using steam, hot water or waste heat to drive the evaporation. Also available with thermal vapour recompression (TVR) enabling less steam consumption.

- Available as pre-assembled module

- Available in ZLD configuration equipped with crystal dewatering decanter centrifuge to produce a dry solids phase, and as stand-alone evaporator.

Documents

Heat sources for evaporation system

Configuration Options

Alfa Laval evaporation systems can use heat from different sources such as mechanical and thermal compression as well as waste vapours from dryers.

Mechanical vapour recompression, MVR

- Low (or no) steam consumption

- Uses electricity

Multiple-effect system

- Saves energy by reusing steam

- Simple and flexible

Thermal vapour recompression, TVR

- Low cost with reduced steam consumption

- Simple, no moving parts

Waste heat from your process

- Utilize low grade steam or waste heat

- Recover energy from exhaust gases

Working principle

Water is fed into the AlfaFlash heat exchanger. After heating fluid is then pushed through the flash orifice. The mixture is now essentially split in two phases – concentrate and vapour, which enters the cyclone separator where centrifugal forces boost vapour liquid separation. Vapour rises into space where mists and fine droplets are removed and the remaining concentrate flows into the recirculation pump. A side stream of concentrated liquid is then pushed through to the decanter where water is separated from solids.

Decanter centrifuge working principle

Alfa Laval decanter technology is used for dewatering suspended solids, resulting in minimum waste and maximum water recovery, with high removal efficiency for micro-particles as well. Watch the video to learn more!

AlfaFlash working principle

Dig deeper into the functions of the AlfaFlash ZLD system. Watch the AlfaFlash animation and experience our forced circulation evaporation technology first hand

Industries and applications

Many industries and companies can benefit from a ZLD solution. The below overview of water-intensive processes and applications can help you identify potential benefits of ZLD operation at your facility

Applications

Reverse osmosis

• Reverse osmosis (RO) reject

Separation and dewatering

• HVO pre-treatment

• Pyrolysis oil wastewater

Storage

• Evaporation ponds

• Taillings ponds

Cooling/Heating

• Cooling tower blowdown

• Boiler blowdown

Scrubbing

• Flue gas desulphurization

• Wet electrostatic precipitator

Cleaning/Washing

• Spent caustic

• CIP waste

• Waste wash water

Metal surface treatment

• Treatment baths

• Washing

Fermentation

• Sugar concentration

Distillation

• Stillage

• Vinasse

Ion exchange

• Ion exchange regeration

waste

Industries

HVO, renewable fuels and bio-based chemicals

Refineries, bioplastic manufacturers and 2G ethanol makers can recycle and reuse wastewater from their renewable energy processes.

Food processing

Manufacturers in the food industry, including those producing soy-based products, oils, meat, and next-generation foods, depend on Alfa Laval's advanced food processing equipment and technologies to stay competitive.

Manufacturing industry and service centres

Service centres, and automotive, tool and electronics manufacturers all need to minimize or even eliminate wastewater to boost profits and achieve sustainability goals.

Beverage processing

Alfa Laval supplies equipment, modules and complete processing lines tailored to meet the specific needs of individual beverage producers and breweries.

Recycling industry

Alfa Laval offer AlfaFlash ZLD systems for crystallization chemical recycling loops (leaching) and more. We can help you with your recycling process and your recycling waste stream.

Industrial water and waste treatment

The transition to more circular business models is essential for being able to operate in a more sustainable way. As industrial processes use significant amounts of water, becoming more circular means first understanding how this water can be treated so it can be saved and reused.

Process industry

AlfaFlash ZLD system and process crystallizers can be used in a variety of processes in the process industry.

Learn more

Watch the videos to learn more about the AlfaFlash ZLD system!

Alfa Laval service centre recycle almost 100 percent of its water

Solutions to clean industrial wastewater and recover value from waste

How our solutions make a difference in recycling applications

Learn more about our test possibilities

Service

When you turn to Alfa Laval for service and parts for your AlfaFlash ZLD system, you experience readiness and reliability that save you time and money while making a responsible choice for safety and the environment. Our global service network means we are ready to support you with what you need, when you need it, and where you need us to be, combining Alfa Laval service expertise with local knowledge and language.

The service offerings and solutions in our Alfa Laval 360° Service Portfolio help you protect your investment throughout its life cycle and ensure that your AlfaFlash ZLD system delivers its promised performance with maximum uptime and operating efficiency.

An Alfa Laval Service Agreement is an individually tailored service contract that combine any of the services in the 360° Service Portfolio to meet your needs and demands.

We partner with you in every aspect over time and based on your requirements we can help with:

- Start-up – professional commissioning support to get your AlfaFlash ZLD system in operation and optimized to perform according to expectations combined with operator training to get your personnel familiarized with the new Alfa Laval equipment.

- Maintenance – preventive maintenance program ensuring worry-free operation and minimized risk for unplanned stops.

- Support – as your capable companion we give you priority to first line support and are available for support and guidance when needed, remote or on site.

- Monitoring – inspections and audits of your equipment as well as continuous monitoring of vital operational equipment data can lead to early detection of possible issues ensuring that action is taken before it is too late.

- Improvements – a range of services that can take your operation to the next level by re-designing or upgrading the equipment to incorporate the latest technological developments.

A widespread distribution and logistics network for spare parts and consumables means we can get you what you need, when you need it.

An Alfa Laval Service Agreement will give you genuine spare parts for guaranteed durability, reliability and equipment life and lower your total cost of ownership.

Compliment your AlfaFlash ZLD system investment by protecting it and making sure it offers years of optimal performance with an Alfa Laval Service Agreement.

We take protecting people and the environment seriously and we make it easier for you to